Welcome to Shenzhen Wanxuan Magnetic Industry Co., LTD.

Material properties

Sintered AlNiCo magnet performance parameter table |

|||||||||

| characteristic | Maximum energy product | Persistent | Coercivity | intrinsic coercive force | Density d | Temperature Coefficient | Curie temperature | Remark | |

| Grade | (BH)max | Br | Hcb | Hcj | α(Br) | Tc | |||

| Grade | kJ/m3 (MGOe) | mT(kG) | kA/m(kOe) | kA/m(kOe) | g/c㎥ | %/K | °C | ||

| S-AINiCo4/1 | 3.2-4.8 | 870-890 | 9-11 | 10-12 | 6.8 | -0.02 | 750 | Isotropic | |

| (0.40-0.60) | (8.7-8.9) | (0.11-0.14) | (0.13-0.15) | ||||||

| S-AINiCo8/5 | 8.5-9.5 | 530-620 | 45-50 | 47-52 | 6.8 | -0.02 | 750 | ||

| (1.07-1.19) | (5.3-6.2) | (0.57-0.63) | (0.59-0.65) | ||||||

| S-AINiCo10/5 | 9.5-11 | 630-700 | 48-56 | 50-58 | 6.8 | -0.02 | 780 | ||

| (1.19-1.38) | (6.3-7.0) | (0.60-0.70) | (0.63-0.73) | ||||||

| S-AINiCo12/5 | 11-13 | 700-750 | 50-56 | 53-58 | 7 | -0.02 | 800 | ||

| (1.38-1.63) | (7.0-7.5) | (0.62-0.70) | (0.66-0.73) | ||||||

| S-AINiCo14/5 | 13-15 | 730-800 | 47-50 | 50-53 | 7.1 | -0.02 | 790 | ||

| (1.63-1.88) | (7.3-8.0) | (0.59-0.63) | (0.63-0.67) | ||||||

| S-AINiCo14/6 | 14-16 | 620-810 | 56-64 | 58-66 | 7.1 | -0.02 | 790 | ||

| (1.76-2.00) | (6.2-8.1) | (0.70-0.81) | (0.73-0.83) | ||||||

| S-AINiCo14/8 | 14-16 | 550-610 | 75-88 | 80-92 | 7.1 | -0.01 | 850 | ||

| (1.76-2.00) | (5.5-6.1) | (0.94-1.11) | (1.00-1.16) | ||||||

| S-AINiCo18/10 | 16-19 | 570-620 | 92-100 | 99-107 | 7.2 | -0.01 | 850 | ||

| (2.00-2.39) | (5.7-6.2) | (1.16-1.26) | (1.24-1.34) | ||||||

| S-AINiCo29/6 | 29-33 | 970-1200 | 58-64 | 60-66 | 7.2 | -0.02 | 860 | anisotropy | |

| (3.64-4.15) | (9.7-12) | (0.73-0.80) | (0.75-0.83) | ||||||

| S-AINiCo30/6 | 30-34 | 1000-1100 | 58-64 | 60-66 | 7.2 | -0.02 | 860 | ||

| (3.77-4.27) | (10-11) | (0.73-0.80) | (0.75-0.83) | ||||||

| S-AINiCo42/10 | 42-46 | 950-1100 | 100-110 | 104-114 | 7.2 | -0.01 | 860 | ||

| (5.27-5.77) | (9.5-11) | (1.26-1.38) | (1.30-1.43) | ||||||

| S-AINiCo33/11 | 33-38 | 700-800 | 107-115 | 111-119 | 7.2 | -0.01 | 860 | ||

| (4.14-4.77) | (7-8) | (1.34-1.45) | (1.39-1.50) | ||||||

| S-AINiCo35/5 | 35-39 | 1100-1200 | 48-52 | 50-54 | 7.2 | -0.02 | 850 | ||

| (4.40-4.9) | (11-12) | (0.60-0.65) | (0.63-0.68) | ||||||

| S-AINiCo37/15 | 37-41 | 700-800 | 140-147 | 150-158 | 7.2 | -0.01 | 870 | ||

| (4.65-5.15) | (7.0-8.0) | (1.76-1.85) | (1.88-1.98) | ||||||

| S-AINiCo39/12 | 39-43 | 830-900 | 115-123 | 119-127 | 7.25 | -0.01 | 860 | ||

| (4.90-5.40) | (8.3-9.0) | (1.45-1.54) | (1.50-1.60) | ||||||

| S-AINiCo44/12 | 44-48 | 900-950 | 119-127 | 124-132 | 7.25 | -0.01 | 860 | ||

| (5.53-6.03) | (9-9.5) | (1.50-1.60) | (1.56-1.66) | ||||||

| S-AINiCo40/15 | 40-48 | 750-850 | 143-151 | 155-163 | 7.2 | -0.01 | 870 | ||

| (5.02-6.03) | (7.5-8.5) | (1.80-1.90) | (1.95-2.05) | ||||||

| S-AINiCo44/15 | 44-48 | 800-880 | 148-160 | 155-163 | 7.2 | -0.01 | 870 | ||

| (5.53-6.03) | (8.0-8.8) | (1.86-2.00) | (1.95-2.05) | ||||||

| Unit conversion: | |||||||||

| Remark 1: Conversion formula between SI unit and CGS unit: 1 mT=10 Gs, 1 kA/m=4тт Oe, 1 kJ/m3=4тт×10-2MGOe; | |||||||||

| Grade description: S-AINiCo 44/15 | |||||||||

| S: S means powder sintered alnico permanent magnet alloy, and the one without S means cast alloy; | |||||||||

| AINiCo: Indicates AlNiCo permanent magnet alloy; | |||||||||

| 44: The maximum magnetic energy product (BH) max (unit KJ/m3), rounded to the nearest integer; | |||||||||

| 15: One-tenth of the minimum value of the coercive force Hc (unit KA/m), rounded to an integer. | |||||||||

|

Cast AlNiCo magnet performance parameter table

|

|||||||||

| characteristic | Maximum energy product | Persistent | Coercivity | intrinsic coercive force | Density d | Temperature Coefficient | Curie temperature | Remark | |

| Grade | (BH)max | Br | Hcb | Hcj | α(Br) | Tc | |||

| Grade | kJ/m3 (MGOe) | mT(kG) | kA/m(kOe) | kA/m(kOe) | g/c3 | %/K | °C | ||

| S-AINiCo12/6 | 12(1.50) | 640(6.4) | 52(6.65) | 56(0.70) | 7 | -0.03 | 810 | equiaxed crystal | Isotropic |

| S-AINiCo13/6 | 13 (1.63) | 750(7.5) | 52(0.62) | 56(0.70) | 7 | -0.03 | 810 | ||

| S-AINiCo18/10 | 18(2.26) | 530(5.3) | 90(1.13) | 97(1.22) | 7.1 | -0.01 | 860 | ||

| S-AINiCo20/11 | 20(2.51) | 600(6.0) | 100(1.26) | 108(1.36) | 7.3 | -0.01 | 860 | ||

| S-AINiCo36/6 | 36(4.52) | 1150(11.5) | 60(0.75) | 62(0.78) | 7.3 | -0.02 | 850 | equiaxed crystal | anisotropy |

| S-AINiCo38/5 | 38(4.77) | 1200(12.0) | 50(0.63) | 52(0.65) | 7.3 | -0.02 | 850 | ||

| S-AINiCo40/5 | 40(5.03) | 1250(12.5) | 49 (0.62) | 50(0.63) | 7.3 | -0.02 | 850 | ||

| S-AINiCo44/5 | 44(5.53) | 1270(12.7) | 52(0.65) | 53(0.67) | 7.3 | -0.02 | 850 | semi-columnar crystal | |

| S-AINiCo52/6 | 52(6.53) | 1300(13.0) | 56(0.71) | 57(0.72) | 7.3 | -0.02 | 850 | columnar crystal | |

| S-AINiCo60/6 | 60(7.54) | 1350(13.5) | 59 (0.74) | 60(7.5) | 7.3 | -0.02 | 860 | ||

| S-AINiCo38/11 | 38(4.77) | 850(8.5) | 110(1.38) | 112(1.41) | 7.3 | -0.01 | 860 | equiaxed crystal | |

| S-AINiCo40/17 | 40(5.02) | 750(7.5) | 156(1.96) | 168(2.11) | 7.3 | -0.01 | 870 | ||

| S-AINiCo46/12 | 46(5.78) | 930(9.3) | 120(1.51) | 124(1.56) | 7.3 | -0.015 | 860 | ||

| S-AINiCo48/16 | 48(6.03) | 820(8.2) | 144 (1.18) | 158 (1.98) | 7.3 | -0.01 | 870 | ||

| S-AINiCo72/12 | 72(9.04) | 1050(10.5) | 114 (1.43) | 116(1.46) | 7.3 | -0.015 | 850 | columnar crystal | |

| S-AINiCo80/12 | 80(10.04) | 1080(10.8) | 120(1.51) | 122(1.53) | 7.3 | -0.015 | 850 | ||

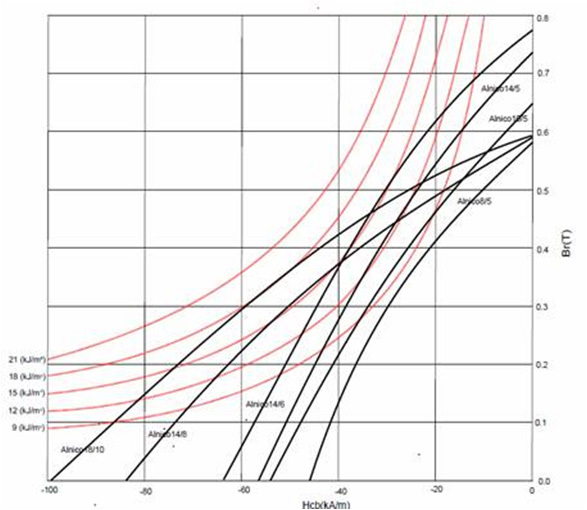

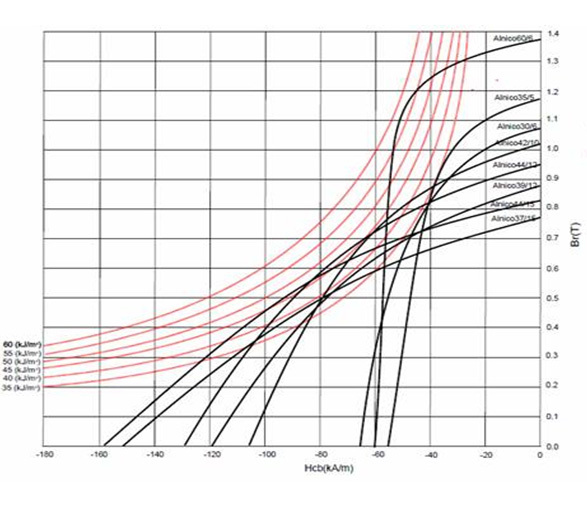

Demagnetization curve:

All directions

Different directions

AlNiCo specification parameter selection table, commonly used AlNiCo specifications, grades and performance, accept customization

Key words:

Alnico